By Zack James, Founder, Rabbit Tractors

By Zack James, Founder, Rabbit Tractors

The modern farm operation has been designed around the tractor, but the modern tractor has been designed around maximizing labor efficiency at the cost of other concerns. At Rabbit Tractors, we are using autonomous driving technologies to remove this design constraint and re- envision farm management practices to maximize yield and environmental stewardship without sacrificing profit.

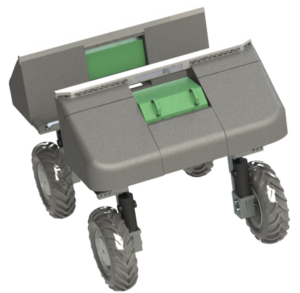

At Rabbit, we are building the world’s first multi-purposed, modular, compact and autonomous “farm utility robot.” Designed specifically for row-crop farmers, it operates in swarms with other Rabbits to achieve the same productivity as large modern tractors without the problems of large tractors

such as soil compaction, huge capital costs, and complex maintenance requirements. These smaller units are more efficient both operationally and energy-wise, are simple in design, and can be assembled in different configurations for use throughout the year. Farmers who utilize our product see an immediate increase in yield and decrease in cost, all while opening the door to a new world of high-tech precision implements and innovative management techniques.

Deploying autonomous tractors in real row crop farm fields has some unique technical challenges that differentiate it from on-road and indoor autonomy. Farm fields are expansive, repetitive, dirty, and remote. The lack of access to cellular or WiFi networks means all computer power must be kept on board the vehicle where cost and environmental protections are driving design criteria. Common applications of technologies like LIDAR and localization break down in dust filled fields with no differentiating features to track. Even GPS sometimes fails on cloudy days or at the edge of the field close to a tree line. One example is path planning, or determining the optimal route through a field. Unlike most applications, agriculture is concerned not with getting from point A to point B, but with covering an area with an implement facing a certain direction. Because these missions can take hours, small efficiency increases, such as minimizing turns and elevation changes, add up to huge absolute time savings.

The adoption of new technology by farmers is also a challenge. This is a group who has seen “the next big thing” come and go dozens of times, and have built a healthy level of skepticism. On top of that, the tractor is the core tool used in the most stressful times of a farm operation. To replace a trusted piece of machinery at a crucial time requires trust in the technology and an understanding of how to operate and troubleshoot it. Farmers need to explore, experiment, and learn a technology before they integrate it fully into their operations. Our first use-cases are selected with this in mind.

The adoption of new technology by farmers is also a challenge. This is a group who has seen “the next big thing” come and go dozens of times, and have built a healthy level of skepticism. On top of that, the tractor is the core tool used in the most stressful times of a farm operation. To replace a trusted piece of machinery at a crucial time requires trust in the technology and an understanding of how to operate and troubleshoot it. Farmers need to explore, experiment, and learn a technology before they integrate it fully into their operations. Our first use-cases are selected with this in mind.

Cover crop seeding and soil sampling take place later in the season or after harvest when there is a relatively large time window to accomplish the task, meaning a technology failure can be remedied. The value-propositions of lowering labor costs, removing human error, and minimizing hours on expensive planting units are easy to understand. Most importantly though, these use-cases demonstrate key features a farmer will be investigating, such as the ability to traverse crops without damaging them and the ability to monitor a complex robotic process autonomously.

Learn more at: rabbittractors.com

Zack James is the founder of Rabbit Tractors. He founded Rabbit Tractors while studying corporate and securities law at the University of Michigan Law School as a solution to his own problem, being able to efficiently operate a farm operation spread over hundreds of miles.

This article was originally written for the annual State of IoT Report, 2020 Edition. Download the entire publication here.

Arabic

Arabic Chinese

Chinese Dutch

Dutch French

French German

German Hindi

Hindi Italian

Italian Japanese

Japanese Korean

Korean Portuguese

Portuguese Russian

Russian Spanish

Spanish